2017

Michindoh Truck and Tractor Pull Association Rules

Rules as of 1/25/2017

All changes

highlighted in yellow.

General Rules:

1. Michindoh Classes are: 6,000lb. Stateline Pro Street 4x4 (points class)

6,200lb. 2wd Super

Stock (points class)

6,200lb.

4wd Altered Stock (points class)

8,500lb.

Pro Farm Tractors (points class)

9,500lb.

Hot Farm Tractors (points class)

5,500lb. Michindoh Modified Rails

(points class)

7,800lb. 2.5

Diesel Trucks (points class)

Open (see rules) 100% Payback

- If at the

end of a given pulling season, any point’s class that had an average

number of entries less than 3 over the course of that season. That class

will be transitioned to a 100% payback and will not be a point’s class for

the following season or may be dropped.

- Class rules

will not change throughout the current year unless there is a safety issue

with a rule. The decision of the board to change a rule deemed to be a

safety issue will require a majority vote of the board.

- All

drivers and vehicles in Michindoh classes must be paid Michindoh members

and possess a Michindoh pulling vehicle number.

- Classes

will have a random pulling order from event to event.

- Drivers in

all classes must be entered before the start of the pull. Late

entries for all classes: If not registered ½ hour before posted start

time, you will be fined $20.00 for late entry fee.

- If you

cannot be at the pull on time, you may pre-enter by contacting someone who

can be there on time.

- If you

break before your class starts, your entry fees will be refunded.

- NO refunds

after class starts.

- The driver

who is on the entry form MUST be the driver in the vehicle. If a

substitute is required, you must notify Michindoh officials before the

vehicle is pulled up to the sled.

- Drivers

that make a full pull MUST be the drivers in the pull off. NO substitution

will be allowed or the pull will be disqualified.

- For general

safety, the Head Tech Official and/or class tech official may inspect a

vehicle at any time. This includes, but does not limit to: pumping for

cubic inch, checking the fuel system and any safety item, under the hood

or in the drive train. All owners/representatives of all vehicles at any

pull site must allow an inspection to be done in his presence. A random

pump ball will be used during registration to select who will be pumped.

Anyone who refuses will be in direct violation of this rule and will be

subject to disqualification under protest teardown rules.

- Only the

official operating the pump and the owner of the vehicle being pumped will

be allowed near the vehicle while being pumped.

- As soon as

the sled returns and/or the start line officials call you, drivers must be

ready to pull. The driver will have THREE MINUTES to hook to the sled and

tighten the chain. After this time, the pull will be forfeited.

- Contestant

will be allowed 2 attempts to start the sled within the first 100 feet of

the pull, at the discretion of the starting flagman. Only 2 attempts

allowed to start the sled in the event of a pull

off. Vehicles’ are not allowed to return to the pits if involved in a pull

off.

- The total

weight of the pulling vehicle includes driver.

- Driver’s

meeting takes precedence over all written rules.

- Idle speed

only while driving in pit area.

- All

electric fuel pumps must be connected through the kill switch.

- All pulling

vehicles must have a 3-1/4” wide x 3-3/4” deep opening due to NTPA rule

changes on weight transfer hooks.

- All pulling

vehicles must have reverse lights (white lights) and neutral start

switches. Light should be mounted near hitch. This is mandatory for

all classes.

- There

will be no “gimme” hooks for any driver or

vehicle.

- All

vehicles must have a working

fire extinguisher.

- Board of

Director has precedence over all.

- All drivers

must wear approved helmets and seat belts.

- All drivers

must have valid state drivers license.

- An owner

cannot change vehicle and keep same vehicle number and or transfer points.

- With an

incorporated safe shut down area, all tracks will be 300 ft long whenever

possible. Rather than starting a class all over, the head judge and sled

operator may utilize some of the shut down area to extend the finish line

to a floating finish if the sled is set properly, as long as the sled will

stop the class within 30 ft of the original finish line. A pulling track

may be shortened from 300 ft, to maintain a 100 ft minimum shutdown.

- Vehicles

must have a one piece, 1/4” hydro form bell housing on any straight shift.

If any modifications are made, modified area must be ground smooth inside

and out. All vehicles using a clutch and flywheel assembly will run a full

block saver plate of 1/8” steel, with all bolts possible installed. Diesel

powered vehicles are exempt from this rule.

- All

flywheels must be steel or aluminum and SFI approved. No cast stock

flywheels allowed. Each vehicle owner will sign a waiver on the membership

form stating that they are running a SFI approved flywheel.

- All

automatic transmissions must have SEMA approved scatter blanket and SFI

approved flexplate.

- Block

spacers to accommodate multiple disc clutches must be as substantial as

the block flange to retain flywheel. This will be at the tech official

discretion.

- All

vehicles must have easy and ample access to hitch to hook chain.

- All Reese

style hitch inserts must be a class 5 or solid insert. With no movement in

any direction.

- Any engine

to be pumped or torn down is allowed 1% max tolerance, due to inaccuracy

of our measuring devices.

- All

vehicles must have working hydraulic brakes capable of sliding the tires

when applied.

Michindoh

Points System

The point’s structure is as follows:

1st 15

place points + 15 hook points 11th 5

place points + 15 hook points

2nd 14 place points + 15 hook points

12th 4

place points + 15 hook points

3rd 13

place points + 15 hook points 13th 3

place points + 15 hook points

4th 12

place points + 15 hook points 14th 2

place points + 15 hook points

5th 11

place points + 15 hook points 15th 1

place points + 15 hook points

6th 10

place points + 15 hook points 16th

and lower will receive zero place points

7th 9

place points + 15 hook points and

15 hook points

8th 8

place points + 15 hook points

9th 7

place points + 15 hook points

10th 6

place points + 15 hook points

Points

Rules:

To be eligible for 15 hook points,

the competitor must compete in a point’s class, and have paid an entry fee,

passed inspection, and paid full

Michindoh membership dues.

Points are awarded to the vehicle, not

to the driver. Each pulling vehicle will receive placing point at each

pulling event. First place will be awarded 15 points,

Second place will be awarded 14 points, and so on.

If a pull is cancelled, 15 “show up” points

will be issued to those vehicles already entered. At the end of season, all

competitors will drop their lowest “place points” from the season. The competitor’s lowest place points may

include a missed event. “Show up” and “Hook“ points

cannot be dropped.

At the end of the pulling season if

there is a tie in points between vehicles in the same class, the distances that

each of the vehicles pulled at each of the events will be added together.

Whoever has the furthest total distance will be awarded the points championship

On-track disqualifications

(i.e. out of bounds, loss of weight, etc) will receive last place points and

last place payout in class. If there is more than one entry disqualified in a

given class, the last place points and payout will be divided equally among the

disqualified entries.

Protest

and Tear Down Rules:

You may protest (if you are Michindoh member in

the same class) to have any vehicle pumped the night of a pull by presenting $350.00 to the president

or vice president present. If found to be illegal by the

pump, the owner may tear down the engine at their expense to prove it legal or

be barred from competition for one year from violation. If the vehicle

in question is found to be legal it will keep the $350.00 pump fee.

You may also protest to have a vehicle

torn down (if you are a Michindoh member in the same class). The person

protesting must bring $750.00 cash to the president or vice president

present. The protest will be discussed. If the vehicle

in question is to be torn down, it will have the option to do it at the track

or at the nearest suitable location. The vehicle or engine will be

impounded until the tear down. The tear down must happen with-in three days of

the protest. If the vehicle in question is found to be legal, all protest fees

will go to the owner.

Any

vehicle found illegal and/or refuses to be protested or teched,

will be barred from competition for one year from violation. Unless, they

are willing to pay a reinstatement fee of $500.00 to the club and prove the

vehicle is legal. Any money and points won the day of the protest will be

returned or withheld by the club. If the vehicle in question refuses to

refund winnings, the amount of those winnings will be added to the

reinstatement fee.

The

tech-official for the class has the right to check any vehicle they feel may be

in violation of any rules without a protest fee with the permission of the

board of directors.

Causes for Disqualification:

1.

Loss

of anything off the vehicle (i.e.: weights, parts, etc.) while it is in motion,

except in the case of breakage in the drive-line, until red flag is waved.

2.

Loss

of safety equipment or failure of safety equipment to function.

3.

Excessive

loss of liquid or steady stream, except in the case of internal breakage.

4.

Illegal

fuel and use of Nitrous Oxide.

5.

Any

part of your vehicle out of bounds from start to finish while under the green

flag.

6.

Unsafe

operations of any vehicle in pits or on track (i.e.: no hole

shots, excessive speed, etc.)

7.

INTOXICATION

of any driver or pit crew member or any smell of alcohol on a driver’s breath.

8.

Illegal

equipment.

9.

Leaving

starting line under red flag.

10. Un-sportsman

like conduct.

11. No reverse in

vehicle.

12. If DQ for

cheating, all points and money will be forfeited.

13. If a DQ

vehicle will receive last place points in the class, and if more than 1 vehicle

is DQ, they share at the bottom of the list in the same order they were

otherwise. Out of bounds only.

Track Preparation:

A Michindoh safety tech or officer will

be in charge of track preparation and maintenance. All event personnel

will be under their supervision. Failure of event personnel to comply

will mean cancellation of the event. This rule has been added to provide

better pulling tracks. Michindoh members will also be required to assist

the officers with other track work as needed at the pulls, such as lining up

pulling vehicles, flagging, etc.

ALL THE ABOVE RULES WILL BE STRONGLY

ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS. THE OFFICIALS’ DECISIONS

ARE FINAL!

**The Head of Class/Tech Official for each

class will enforce all of the rules! Every vehicle will be teched on a random basis at some point throughout the

season.**

6200lb. 4wd Altered Stock

Rules locked, 2016, 2017

With

the exception of safety requirements approved by the board.

Must also follow all general rules

listed above.

1. Hood modifications

and upright headers are acceptable.

2. Tires must be D.O.T. approved for highway use

and uncut. No recaps.

3. Protest rules in effect.

4. The

decisions of the pulling officials are final.

5. Kill switches are mandatory. Electric

fuel pumps must be wired through the kill switch.

6. Trucks must have a full body, no flat beds, if bed floor is removed it must be covered and not

visible to spectators.

7. Will allow racing seat.

8. Fuel

tanks are allowed to be in front of vehicle if they are S.F.I. and have braided

hoses and pressure coupler. Batteries may be mounted out in front of the truck

but battery must be enclosed. No

Batteries in cab.

9. All drivers are required to wear full face

helmets and jackets and pants with a SFI rating of 3-2a-1. Shoes also

recommended.

10. All drivers

are required to wear seatbelts.

11. All vehicles

must have a working

fire extinguisher.

Weights:

1. Front weights

to be a maximum of 60” from center of front axle.

2. No loose

weights in cab.

Hitches:

1. Maximum hitch

height is 26 inches, & minimum 42 inches from center of rear end maximum of

48 inches.

2. You must use

a steel plate hook point with a minimum 3 ¼ wide 3 ¾ deep hole.

3. Pivot point

of hitch cannot be forward of center of rear axle. It must be below top of

frame rails, and hook point must be behind frame rail or body.

4. Hitches

must be tight and have no movement in any

direction.

Engines:

1. Maximum 514

cubic inch limit.

2. Any single

four-barrel carburetor is allowed.

3. No turbochargers

or superchargers.

4. No fuel injection

unless factory equipped.

5. Cast iron

block and heads only, except FORD FE allowed to run aluminum cylinder heads.

6. Aluminum

intake may be used.

7. No

pressurized fuels. No methanol alcohol fuel.

8. Front of

engine block cannot extend more than 10 inches of the center of the front axle.

Front axle must be in stock location.

Harmonic Balancer:

1.

All engines must be equipped with a harmonic

balancer or dampener meeting SFI Spec18.1.

2.

All vehicals

are required to shield all rotating mass mounted on the front of the crankshaft,

if unobstructed. Shields to be from frame rail to frame rail and top to bottom.

Shields to be a minimum of .125” steel or aluminum fastened by at least 2

evenly spaced 3/8” grade 5 bolts.

Transmissions & Drivelines:

1. Maximum wheel

base 134 inches center to center.

2. Stock type

one ton or two ton drive-lines are permitted. No planetary.

3. Drop box’s are allowed.

4. May block frame

solid.

5. Must have

scatter proof bell housing or automatic transmission blanket, and S.F.I flywheels

U-joint

shielding:

1.

All u-joints and yokes must have a 360

degree cover, at least 6” long (covering entire yoke and u-joint), 1/4” thick

steel (3/8” thick aluminum). Inside diameter of shield will be no more than

2" larger than u-joint. If cover is cut in half it must be fastened no

farther than 1” from ends with at least 3/8”- grade 8 bolts. Must be bolted a

maximum of 6” from bolt to bolt. All intermidiate

shafts need covered 360 degrees. NO HINGE STYLE fasteners permited.

Must be securly fastened.

Drive

shaft loops:

1.

Drive shaft loops required (3/4” or

wide), 1/8” or thicker steel (1/4” or thicker aluminum). No more than 2” larger

than the largest u-joint. If cut in half, must be bolted within 1” from ends

and a maximum of 16” apart from loop to loop (multiple loops). If using a one

piece cover it must be bolted a maximum of 6” apart the entire length and at

least 1” from ends. All fasteners must be at least 3/8”- grade 8 bolts. NO

HINGE STYLE permited. Must be securly

fastened.

ALL THE ABOVE

RULES WILL BE STRONGLY ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS.

THE OFFICIALS’ DECISIONS ARE FINAL!

**The

Head of Class/Tech Official for each class will enforce all of the rules!

Every vehicle will be teched on a random basis at

some point throughout the season.**

6200lb. 2wd Super Stock

RULES LOCKED

2016, 2017, 2018

With the exception of Safety

requirements approved by the Board.

Must also follow all general rules

listed above.

Engines:

1.

Maximum single 485 cubic inch 1% tolerance, naturally aspirated V8 engine.

2.

Cylinder heads: two valves and one spark plug per cylinder. Aluminum heads are

allowed. No less than 24 degree head. No Hemi heads.

3.

Legal aluminum heads: CHEVROLET: dart-320, 360, and Pro 1, Brodix

1 & 2, and all Edelbrock. FORD: Cobra jet, Blue

Thunder and TFS A460. CHRYSLER: Indy 444-1. Not limited to these heads, but

must meet A & B.

3a.

Must have cast aluminum manifold.

3b.

Must except stock rocker arm assembly.

4.

The front of the engine block cannot extend more than 160 inches forward of the

center of the rear axle or 20 inches forward of the center of the front

axle.

5.

One carburetor, gasoline only, no pressurized fuels, no methanol.

Harmonic Balancer:

3.

All engines must be equipped with a harmonic

balancer or dampener meeting SFI Spec18.1.

4.

All vehicals

are required to shield all rotating mass mounted on the front of the

crankshaft, if unobstructed. Shields to be from frame rail to frame rail and

top to bottom. Shields to be a minimum of .125” steel or aluminum fastened by

at least 2 evenly spaced 3/8” grade 5 bolts.

Hitches:

1.

Maximum height 30 inches.

2.

Minimum 36 inches behind center of rear axle.

3.

Maximum 48 inches behind center of rear axle.

4.

Pivot point of the hitch can not be forward of the

center of the rear axle.

5.

Must be rigid at all hook points.

6.

Must be no smaller than a 3 ¼ deep 3 ¾ wide opening at the hook point.

Tires & Wheels:

1.Can run any size

street legal DOT tire. Maximum size 35x12.50 or

315-70-16 metric. Can run 34X18.0X15 pulling tires

allowed.

2.

No split rims; snap rings or dual wheels.

Transmissions & Drivelines:

1.

Stock altered frames. No tube chassis.

2.

Maximum wheel base 140 inches center to center.

3.All u-joints and yokes must have a

360 degree cover, at least 6” long (covering entire yoke and u-joint), 1/4”

thick steel (3/8” thick aluminum). Inside diameter of shield will be no more

than 2" larger than u-joint. If cover is cut in half it must be fastened

no farther than 1” from ends with at least 3/8”- grade 8 bolts. Must be bolted a maximum of 6” from bolt to bolt. All intermidiate shafts need covered 360 degrees. NO HINGE

STYLE fasteners permited. Must be securly

fastened.

4. Drive shaft loops required (3/4” or

wide), 1/8” or thicker steel (1/4” or thicker aluminum). No more than 2” larger

than the largest u-joint. If cut in half, must be bolted within 1” from ends

and a maximum of 16” apart from loop to loop (multiple loops). If using a one

piece cover it must be bolted a maximum of 6” apart the entire length and at

least 1” from ends. All fasteners must be at least 3/8”- grade 8 bolts. NO

HINGE STYLE permited. Must be securly

fastened.

5. Must have a fully enclosed S.F.I. approved explosion proof bell housing on

standard transmission.

6.

Must have S.F.I. approved flywheels for both automatic and standard

transmissions.

7.

Automatic transmissions must have S.F.I. approved flywheel shield and

transmission blanket, or tunnel shield.

8.

Any rear axle is allowed.

Weights & Safety Rules:

1.

Weights can be mounted anywhere on the truck in safe manner. No Loose weights

in cab.

2.

Weights cannot extend more than 60 inches forward of the center of the front

axle, or any part of the truck.

3.

Driver must wear seatbelt.

4.

Batteries must be in protective case and must have a battery disconnect switch

on outside if mounted in front. No batteries in cab.

5.

Must be mounted and working fire extinguisher in the cab.

6.

No gas tanks in the cab.

7.

Must have working kill switches and they will be checked.

8.

Brakes must hold vehicle.....steering brakes are allowed.

9.

Must have radiator overflow.

10.

Drivers must be at least 16 years of age and have a valid driver’s license.

11.

No car bodies, vans, blazers, broncos, or fiberglass bodies allowed. With fiberglass hoods being the only exception.

12.

Hood required covering as much area as possible.

13.

Engine side shields required (.100 for steel and .125 for aluminum), unless

inner fenders are installed.

14.

No holes in firewall or floor larger than 1 inch.

15.

Balancer must be S.F.I. approved or covered 360 degrees.

16.

Nerf bars at least 8 inches behind clevis or body to prevent injury.

17.

Fuel tanks are allowed to be in front of vehicle if they are S.F.I. approved

and have braided hoses and pressure coupler.

18.

2wd- must have wheelie bars. Maximum ground clearance of 6", and 18"

behind rear end.

19.

All drivers are required to wear full face helmets, jackets, pants with a SFI

rating of 3-2a-1and 3.3/5 shoes recommended.

ALL THE ABOVE RULES WILL BE STRONGLY

ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS. THE OFFICIALS’ DECISIONS

ARE FINAL!

**The Head of Class/Tech Official for each

class will enforce all of the rules! Every vehicle will be teched on a random basis at some point throughout the

season.**

6000

lb. Stateline Pro-Street 4wd

Rules locked

2016, 2017, 2018

With

the exception of safety requirements approved by the board.

Must also follow all general rules

listed above.

General Rules:

1. Drivers must

wear approved full face helmet, approved fire jackets and pants with a SFI

rating of 3-2a-1, and seatbelts, SFI shoes recommended.

2. Cowl

induction hood allowed-No open holes.

3. Tires must be

D.O.T. approved for highway use 33x12.50 inches, or 305-70-16 metric maximum

tires size. No cut tires, No boggers. No recaps.

4.

One ton driveline or less, u-joints, driveshaft, rear end, transmission and

transfer case.

Trucks must have complete suspension in factory location with at least 1” of

travel but may be temporally blocked to pull. All rear-end bars must be forward

of rear axle.

5. No special

bumpers, snowplow hook ups, or brush guards. Front bumper must be in stock

location and nothing protruding beyond the bumper.

6. The decisions

of the pulling officials are final.

7. Trucks must

have reverse lights of some sort.

8. Must have scatter-proof

bell housing or blanket, and a kill switch.

9. Any unsafe

manner of vehicle (on or off track) will be disqualified.

10. Top 3

placing trucks may be teched after pull. Any truck in

violation will forfeit placing and hook fees, Tear down and protest rules

apply.

11. Fuel cells

can be added but must be secured inside the bed or under the bed.

12. All drive

lines in factory location, maximum wheelbase 134 inches. No narrowing of the

front or rear axle, 3 rear leaf springs minimum. (No

moving axles or transmission or engines).

13. Truck must

have a full body. No gutting of truck. Trucks must have full bed and a solid

floor made of metal or wood with rear inner fenders and all factory glass. No

flatbeds.

14. Any truck

that has been lightened in any way may be penalized by adding weight to the

rear of the vehicle at the discretion of the tech official.

15. All vehicles

must have a working

fire extinguisher.

16. Must have

working brakes on all 4 wheels.

17. No batteries

in cab.

Weights:

1.

Weight

can be added, but must be secured and not visible in the front of the vehicle.

Weight must be secured and can be visible in the bed of the truck.

Hitches:

1. Hitch (may be change by board due to

track conditions) is to be no

more than 22 inches

off the ground, and hook point must be 42 inches minimum from center rear

axle. All vehicles must have easy and

ample access to hitch to hook chain. Pivot point of hitch cannot be forward of

center of rear axle and must be below top of frame rail. No bars or chains from

hitch to axle. All bars or hitch components must fasten to the frame rail only.

Hitch opening must be 3 ¼ wide by 3 ¾ deep.

2. Hitches must

be tight and have no movement in any direction.

Engines:

1. Maximum 472

cubic inch, naturally aspirated. Engines must be in factory location.

2. Single four

barrel carburetor, maximum 4150 flange allowed. No Dominator, King Demon,

or predator carburetors allowed.

3. No fuel injection.

4. Cast iron

block and heads must be used. No aluminum blocks or heads. All blocks and

heads must have OEM part number. Automotive production block only. No Merlin, Dart, Bowtie, or SVO parts. No hemi heads.

5. Aluminum

intakes are allowed.

6. Headers are

allowed. All exhausts must run through the muffler and be at least to the rear

of cab.

7. No magnetos.

8. Electric

water pumps are allowed.

9. Race fuel is

allowed, No alcohol, LP, or Nitrous oxide.

10. All engines

are required to have a S.F.I. approved balancer and flywheel.

Harmonic Balancer:

1.

All engines must be equipped with a harmonic

balancer or dampener meeting SFI Spec18.1.

2.

All vehicals

are required to shield all rotating mass mounted on the front of the

crankshaft, if unobstructed. Shields to be from frame rail to frame rail and

top to bottom. Shields to be a minimum of .125” steel or aluminum fastened by

at least 2 evenly spaced 3/8” grade 5 bolts.

U-joint

shielding:

1. All u-joints and yokes must have a 360 degree cover,

at least 6” long (covering entire yoke and u-joint), 1/4” thick steel (3/8”

thick aluminum). Inside diameter of shield will be no more than 2" larger

than u-joint. If cover is cut in half it must be fastened no farther than 1”

from ends with at least 3/8”- grade 8 bolts. Must be bolted a

maximum of 6” from bolt to bolt. All intermidiate

shafts need covered 360 degrees. NO HINGE STYLE fasteners permited.

Must be securly fastened.

Drive

shaft loops:

2.

Drive shaft loops required (3/4” or

wide), 1/8” or thicker steel (1/4” or thicker aluminum). No more than 2” larger

than the largest u-joint. If cut in half, must be bolted within 1” from ends

and a maximum of 16” apart from loop to loop (multiple loops). If using a one

piece cover it must be bolted a maximum of 6” apart the entire length and at

least 1” from ends. All fasteners must be at least 3/8”- grade 8 bolts. NO

HINGE STYLE permited. Must be securly

fastened.

ALL THE ABOVE RULES WILL BE STRONGLY

ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS. THE OFFICIALS’ DECISIONS

ARE FINAL!

**The Head of Class/Tech Official for each

class will enforce all of the rules! Every vehicle will be teched on a random basis at some point throughout the

season.**

9,500lb.

Hot Farm Tractors

Rules

locked 2016, 2017, 2018

With the exception of safety requirements approved

by the board.

Must also follow all general rules

listed above.

Engines:

1.

Maximum 540 cubic inch limit, 1% tolerance.

2.

Water injection is allowed. No oxygen carriers or combustion accelerators

allowed. Water only.

3.

Factory after cooler allowed. AGRICULTURE/OEM USE ONLY.

4.

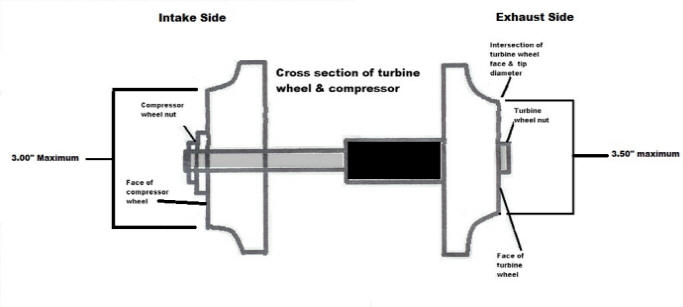

Turbo limited to 3" inlet, 3 1/2" outlet.

a.

Compressor wheel must protrude into the 3” bore at least 1/8 inch.

b.

All turbine wheel blades must protrude into the 3.5 bore at least 1/8 inch

c. Intake and

exhaust will be measured at the intersection of the wheel face and tip diameter.

d. No variable

geometry turbo.

5.

No additional openings in compressor housing outside the 3” opening. MWE groove

is allowed to be open no more than .200.

6.

Factory cast iron cylinder head and block, no aluminum or deck plates.

7.

Diesel fuel only, no additives or pressurized fuels,

NTPA fuel guidelines 409.

8.

Stock appearing manifolds, intakes and exhaust.

9.

Maximum of two valves per cylinder.

10.

Engines must be from same manufacturer and must bolt in stock location without

modification.

a.

Any

and all engine upgrades must not cross manufacturer’s lines and must be

approved by class members and Board of Directors.

i.

Class members

and Board of Directors have approved the use of a 12 valve 5.9L Cummins in an

Oliver 16xx-18xx series chassis.

11.

Mechanical fuels systems only. No computerized or electronically controlled

fuel systems. No ice on board.

Hitches:

1.

Hitch height is maximum of 20 inches.

2.

Must be within 18 inches to 30 inches behind the center of the rear axle.

3.

Must be ridged with no movement in all directions.

4.

No more than 11/2 inch difference between hitch mounting point and hitching

point.

5.

Hook hole is required to be a minimum of 3 ¼ wide 3 ¾ deep opening ID (allow

ample room for person hooking the chain).

Tires & Wheels:

1.

Maximum tire size 20.8/38.

2.

Cut tires are allowed.

3.

Front tires must track rear tires.

Safety:

1.

Emergency air shut-off is mandatory (must be easily accessible to person

hooking the chain).

2.

If equipped with an electric fuel pump, tractor must have a

electric kill switch wired to the emergency air-shut-off.

3.

Must have a mandatory manual three-way dump valve ahead of

the injection pump, to be operated by the driver.

4.

Must have working

fire extinguisher that is within reach of the driver.

5.

Must have working, individual rear brakes. Must have needle

bearing cross in differential.

6.

Must have wheelie-bars.

7. Must have clutch blanket or steel shield

installed 270 degrees 3/8 inch thick, and 12 inches wide.

8.

Seat belts required.

9.

Roll over protection mandatory. 3 bar roll cage manufactured from 2” ODx.120

wall.

10.

Must have a steel flywheel and clutch assembly.

11.

Side shields-Engine side shields are mandatory. Shields must be solid and

minimum of .060” thick steel, or .120” thick aluminum.

a. All in line

engines are required to have an additional inner side shield consisting of

.125” thick steel, or .250” thick aluminum inside the current side shields.

This shield is independent of the current shield and must extend from the

bottom of the head to the centerline of the crankshaft and extend the full

length of the block on each side of the engine.

12.

All inline turbocharged engines are required to have one 3/8” or larger cable

that surrounds the engine block and head. This cable must be placed between the

first and second cylinder. Cable must have 2 clamps at the splice and have no

more than 4” of slack.

13.

Tie-bars securing front frame rails to rear axle housing are mandatory.

14.

All drivers are required to wear full face helmets and jackets and pants with

SFI rating of 3-2a-1 and shoes with a SFI 3.3/5 rating.

15.

Must have 2-3/8” bolts in a cross pattern installed in exhaust pipe.

16.

Front skies are mandatory. All tractors must have skid plates mounted in line

with each frame rail and extended from the center of axle forward (on both

sides) equal in strength to frame rail material. Skid must be securely mounted

and braced to the cassis. Recommended skid surface to be a minimum of 4 inches

wide and 12 inches long with a minimum of 6 inches curve when measured from the

front of most part of rolled edge. Maximum ground clearance is bottom of wheel

rim not to exceed 4 inches with front tires in normal position.

Harmonic Balancer:

1.

All engines must be equipped with a harmonic

balancer or dampener meeting SFI Spec18.1.

2.

All vehicals

are required to shield all rotating mass mounted on the front of the

crankshaft, if unobstructed. Shields to be from frame rail to frame rail and

top to bottom. Shields to be a minimum of .125” steel or aluminum fastened by

at least 2 evenly spaced 3/8” grade 5 bolts.

Appearance:

1.

Tractor must be in stock appearance, hoods, grills, & fenders, (except

injection pump & after cooler).

2.

All tractors that utilize tube ladder-type frames must be covered on outside

with steel or aluminum 0.060 thick.

3.

Maximum wheel base is 114”.

4.

Maximum length is 13’ from center of rear axle to forward-most part of tractor,

including weights, not including front hitch.

5.

Stock bell housing, stock transmission housing, and stock final drive housing

or manufacture’s replacement. No component chassis.

ALL THE ABOVE RULES WILL BE STRONGLY

ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS. THE OFFICIALS’ DECISIONS

ARE FINAL!

**The Head of Class/Tech Official for each

class will enforce all of the rules! Every vehicle will be teched on a random basis at some point throughout the

season.**

8,500lb. Pro Farm Tractors

Rules locked 2016. 2017, 2018

With the exception of safety requirements approved by the board.

Must also follow all general rules

listed above.

Engines:

1.

Maximum 510 cubic inch limit, 1% tolerance.

2.

Water injection is allowed. No oxygen carriers or combustion accelerators

allowed. Water only.

3.

Turbo are limited to 3" inlet x 3.5” outlet.

a.

Compressor wheel must protrude into the 3” bore at least 1/8 inch.

b.

All turbine wheel blades must protrude into the 3.5” bore at least 1/8 inch.

c. Intake and

exhaust will be measured at the intersection of the wheel face and tip

diameter.

d.

No variable geometry turbo.

4.

No additional openings in compressor housing outside the 3" opening. MWE

groove is allowed to be open no more than .200.

5.

Factory cast iron cylinder head and block no aluminum and

no deck plates.

6.

Diesel fuel only, no additives or pressurized fuels,

NTPA fuel guidelines 409.

7.

Stock appearing manifolds, intake and exhaust.

8.

The largest fuel injector pump allowed will be a Bosch P series pump with only

one plunger per cylinder.

9. Maximum of two valves per cylinder.

10.

Engines must be from same manufacturer and must bolt in stock location without

modification.

b.

Any

and all engine upgrades must not cross manufacturer’s lines and must be

approved by class members and Board of Directors.

i.

Class members

and Board of Directors have approved the use of a 12 valve 5.9L Cummins in an

Oliver 16xx-18xx series chassis.

11.

Mechanical fuels systems only. No computerized or electronically controlled

fuel systems. No ice on board.

Hitches:

1.

Hitch height is maximum of 20 inches.

2.

Must be within 18 inches to 30 inches behind the center of the rear axle.

3.

Must be ridged with no movement in all directions.

4.

No more than 1 1/2 inch difference between hitch mounting point and hitching

point.

5.

Hook hole is required to be a minimum of 3 ¼ wide 3 ¾ deep opening ID.

Tires & Wheels:

1.

Maximum tire size 18.4/38.

2.

Front tires must track rear tires.

Safety:

1.

Emergency air shut-off is mandatory (must be easily accessible to person

hooking the chain).

2.

If equipped with an electric fuel pump, tractor must have an electric kill

switch wired to the emergency air-shut-off.

3.

Must have a manual three-way dump valve ahead of the injection pump, to be

operated by the driver.

4.

Must have working

fire extinguisher that is within reach of the driver.

5.

Must have working, individual rear brakes. Must have needle

bearing cross in differential.

6.

Must have wheelie-bars.

7.

Must have clutch blanket or steel shield installed 270 degrees 3/8 inch thick,

and 12 inches wide.

8.

Seat belt required.

9.

Roll over protection mandatory. 3 bar

roll cage manufactured

from 2" OD x .120 wall.

10.

Must have a steel flywheel and clutch assembly.

11.

Side shields – Side shields are mandatory. Shields must be solid and minimum of

.060” thick steel, or .120” thick aluminum.

a. All in line

engines are required to have an additional inner side shield consisting of

.125” thick steel, or .250” thick aluminum inside the current side shields.

This shield is independent of the current shield and must extend from the

bottom of the head to the centerline of the crankshaft and extend the full

length of the block on each side of the engine.

12.

All inline turbocharged engines are required to have one 3/8” or larger cable

that surrounds the engine block and head. This cable must be placed between the

first and second cylinder. Cable must have 2 clamps at the splice and have no

more than 4” of slack.

13.

Tie-bars securing front frame rails to rear axle housing are mandatory.

14. All

drivers are required to wear full face helmets and jackets and pants with SFI

rating of 3-2a-1. Shoes SFI 3.3/5 required.

15.

Must have 2-3/8” bolts in a cross pattern installed in exhaust pipe.

16.

Front skies are mandatory. All tractors must have skid plates mounted in line

with each frame rail and extended from the center of axle forward (on both

sides) equal in strength to frame rail material. Skid must be securely mounted

and braced to the cassis. Recommended skid surface to be a minimum of 4 inches

wide and 12 inches long with a minimum of 6 inches curve when measured from the

front of most part of rolled edge. Maximum ground clearance is bottom of wheel

rim not to exceed 4 inches with front tires in normal position.

Harmonic Balancer:

1.

All engines must be equipped with a harmonic

balancer or dampener meeting SFI Spec18.1.

2.

All vehicals

are required to shield all rotating mass mounted on the front of the

crankshaft, if unobstructed. Shields to be from frame rail to frame rail and

top to bottom. Shields to be a minimum of .125” steel or aluminum fastened by

at least 2 evenly spaced 3/8” grade 5 bolts.

Appearance:

1.

Tractor must be in stock appearance, hoods, grills, & fenders.

2.

All tractors that utilize tube ladder-type frames must be covered on outside

with steel or aluminum 0.060 thick.

3.

Stock bell

housing, stock transmission housing, and stock final drive housing or

manufacturer’s replacement. No component chassis.

4.

Maximum wheel base is 114”.

5.

Maximum length is 13’ from center of rear axle to forward-most part of tractor,

including weights, not including front hitch.

ALL THE ABOVE RULES WILL BE STRONGLY

ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS. THE OFFICIALS’ DECISIONS

ARE FINAL!

**The Head of Class/Tech Official for each

class will enforce all of the rules! Every vehicle will be teched on a random basis at some point throughout the

season.**

7,800# 2.5 DIESEL TRUCK

This class is

designed for pickup trucks with a wide variety of performance upgrades.

Both 4x4 and 2WD-24” hitch (Board will adjust 2wd hitch height as

needed)

Must also follow all general rules

listed above.

With the exception of safety requirements approved

by the board.

Ballast:

1. Hanging front weights and weight

boxes (with weights only) are permitted. If used, ballast must be securely fastened.

2. Weight or weight bracket must not extend

more than 60 inches from the center line of the axle. Final decisions rest with

the technical department.

3. Weights and brackets must be

removable by hand.

Batteries:

1.

The batteries must be securely mounted.

They may not be located in the driver compartment or forward of the radiator

core support.

Body:

1.

The body must be the OEM truck body

including the full bed floor.

2.

The body must retain full sheet metal.

3.

The complete OEM firewall and complete

OEM floor pan is mandatory.

4.

A factory installed pickup bed or

commercial style aftermarket bed must be installed.

Brakes:

1.

Front

brakes are required. Four wheel hydraulic functional brakes are recomended. No driveline

brakes.

Chassis:

1.

The OEM chassis is mandatory

2.

The engine must be in the OEM location.

3.

The vehicle must retain the full OEM

chassis.

4.

Wheel tubes, back half conversions, tube

chassis, etc, are prohibited.

Cooling system:

1.

Radiators must be in stock location and

be of at least stock size.

Credentials:

1.

All drivers must have a valid state drivers license.

Driveline:

1.

An OEM transmission and transfer case

are mandatory. They must have been an option on a one ton or smaller pickup.

Driver Restraint System:

1.

The OEM restraint system or SFI 5

point harness is mandatory and must be worn with a DOT approved seat.

Driveshaft Loops:

1.

Drive shaft loops required (3/4” or

wide), 1/8” or thicker steel (1/4” or thicker aluminum). No more than 2” larger

than the largest u-joint. If cut in half, must be bolted within 1” from ends

and a maximum of 16” apart from loop to loop (multiple loops). If using a one

piece cover it must be bolted a maximum of 6” apart the entire length and at

least 1” from ends. All fasteners must be at least 3/8”- grade 8 bolts. NO

HINGE STYLE permited. Must be securly

fastened.

U-joint

shielding:

1.

All

u-joints and yokes must have a 360 degree cover, at least 6” long (covering

entire yoke and u-joint), 1/4” thick steel (3/8” thick aluminum). Inside

diameter of shield will be no more than 2" larger than u-joint. If cover

is cut in half it must be fastened no farther than 1” from ends with at least

3/8”- grade 8 bolts. Must be bolted a maximum of 6” from bolt to bolt. All intermidiate shafts need covered 360 degrees. NO HINGE

STYLE fasteners permited. Must be securly

fastened.

Engine:

1.

The engine is limited to a stock appearing

OEM compression engine, available from the factory in a one ton or smaller

truck.

2.

Cubic Inch limit of 444CI

3.

Block must circulate coolant freely. No

hard filled blocks. Water pumps may be factory or electric powered.

4.

All factory belt driven accessories,

excluding the air conditioning compressor, must be retained and powered via the

crankshaft by a standard serpentine “v” belt. Electric cooling fans are

permitted.

5.

No individual runner intake manifolds.

(Example: ZZ-customs.). Belt driven alternator. No deck plates. EXAMPLE: NO

HAMILTON HEADS FOR THE CUMMINS AND NO BRODIX HEADS FOR THE DURAMAX.

Exhaust:

1.

All vehicles must be equipped to direct

exhaust upward. The exhaust must exit rearward of the drivers compartment.

Stacks exiting through the fender well and hood are prohibited.

2.

Two (2) 3/8 inch diameter bolts must be

installed through exhaust pipe in a cross pattern within one (1) inch of each

other and as close to the turbo as possible. This will be teched.

Bolt heads welded to the pipe or sheet metal screws to mimic this will be

disqualified.

Fire Extinguisher System:

1.

A working fire extinguisher system is permitted, it

must be securely mounted.

2.

All must have at least a 2 ½ lb

extinguisher with a working gauge mounted within drivers reach.

Fuel:

1.

The fuel must be pump #1, #2 diesel or

Soy/Biodiesel. Fuel must be commercially available.

2.

A fuel cell may be used in place of the

factory fuel tank, but must be mounted in factory location or securely mounted

in bed, no fuel tank in cab.

Fuel Injection Pump:

1.

The fuel injection pump is limited to

cylinder number specific (i.e. 6 cylinder pump on a 6 cylinder motor).

2.

The use of multiple high pressure common

rail fuel pumps or HPOPs are permitted.

3.

P pumps that are allowed are the p3000

and the p7100. Ag governors are allowed.

4.

No Sigma or 12 cylinder pumps allowed.

Harmonic Balancer:

3.

All engines must be equipped with a

harmonic balancer or dampener meeting SFI Spec18.1.

4.

All vehicals

are required to shield all rotating mass mounted on the front of the crankshaft,

if unobstructed. Shields to be from frame rail to frame rail and top to bottom.

Shields to be a minimum of .125” steel or aluminum fastened by at least 2

evenly spaced 3/8” grade 5 bolts.

Intercoolers:

1.

Factory style or aftermarket air to air replacement

only in stock location.

**water to air coolers are prohibited**

2.

Any means of cooling the air before the

engine, except the air to air cooler is prohibited. **No use of ice or

water**

Hitch:

1.

The hitch must be a REECE receiver-style

hitch.

2.

Reinforcements are permitted.

Reinforcements must not extend forward of the center line of the rear axle and

must remain inside the frame rails.

3.

The hooking point must be the rear most

point on the vehicle and must be rearward of the stock location of the tailgate.

4.

The hitch must be horizontal to the

ground and stationary in all directions. Bumper may be notched or removed.

5.

The

hitch height from the ground may not exceed 24”. 2WD will be adjusted by board approval at any time.

6.

The hooking point must have a minimum of

3 ¼ wide by 3 ¾ deep opening for sled hook.

7.

The hooking point must be a minimum of

44 inches from the center of the rear axle, to the end of the hole where the

hook touches metal to be pulled from, this is the hooking point.

Kill Switches:

1.

All trucks are required to have a kill

switch located on the back of the truck, located near the hooking point.

a.

On trucks with an electric injection

fuel pumps it must have an electric shut off or disconnect for the injection

pump on the back of the truck.

b.

Trucks with a manual injection pumps

must have an air guillotine of the spring loaded type, no butterfly type to

kill the air intake to the engine. It is recommended to have an air shut off on

all trucks.

c.

Kill switch failure will result in

disqualification.

Nitrous Oxide/Propane:

1.

Nitrous Oxide, propane, or other oxygen

extenders are prohibited. All system components must be removed from the truck.

2.

No pressurized bottles.

Rear End:

1.

Non OEM rear end housings are

prohibited. The rear end housing must have been for a one ton or smaller pick

up. Rear axle bolts must be covered with a cap or shield.

Safety Equipment:

1.

All drivers are required to wear full

face helmets, jackets and pants with a SFI rating of 3-2a-1, and SFI rating SFI

3.3/5 shoes recommended.

2.

Seat belts are required.

Steering:

1.

The vehicle must retain the full,

original OEM, factory steering gear.

2.

The vehicle must retain the original OEM

power assistance, if it was so equipped.

3.

Additional stabilizers are permitted.

Street Equipment:

1.

Complete headlamp and tail lamp

assemblies are mandatory and must be operative, except the right front headlamp

may be removed for air inlet to engine.

2.

Complete OEM windshield and all other

windows are mandatory.

3.

Driver window must be able to operate

per factory specifications (open and close).

4.

Must have full interior, but may remove rear

seat for weight.

5.

Hand throttle permitted (must be a deadman style)

Suspension-Front:

1.

The factory suspension configuration

must be retained.

2.

Modifications to the front suspension

that would alter the original location(i.e. moving it

forward or backward) is not permitted.

3.

Strut tower braces, lower tie bars, sway

bars, and limit straps are permitted.

4.

Traction bars and devices are permitted

5.

Air shocks are prohibited.

Suspension-Rear:

1.

An OEM style suspension is mandatory.

2.

Traction bars and devices are permitted,

they must be bolt on only, welds are permitted for

attachment to frame or axle housing. Traction bars if installed must have a

chain or cable or some type of safety device mounted one (1) foot from the

front support to catch the bar in case of failure.

3.

Control arms may be strengthened or

replaced, providing all original mounting points are retained and used.

4.

Sway bars, lower tie bars, limit straps,

and camber kits are permitted.

5.

The rear suspension can be solid with a

removable block.

6.

Air bag spring assist and air shocks are

prohibited.

Tires:

1.

The tires must be DOT street tires

2.

Cut tires are prohibited.

3.

The vehicle must retain the original

factory wheelbase and track width.

4.

35x12.50 inch max.

5.

No chains or studs.

6.

Single tires. No duals.

Transfer Case:

1.

Non OEM transfer cases are prohibited.

It must have been an option on a one ton or smaller pick up

truck.

Transmission-Automatic:

1.

Non-OEM transmissions are prohibited.

The transmission must have been an option for a one ton or smaller truck.

Aftermarket torque converters, valve bodies and internal components are

permitted. Transmission brakes are prohibited. Any non-OEM floor mounted

automatic shifter must be equipped with a spring-loaded positive reverse

lockout device to prevent the shifter from accidently being put into reverse.

2.

A functional neutral safety switch is

mandatory. Vehicle must not start in gear.

3.

All transmission lines must be metallic

or high pressure type hose.

4.

All automatic transmissions must be

equipped with a transmission shield meeting SFI Spec 4.1 and must be labeled

accordingly. A blanket type shield must be used and appropriately labeled as

meeting SFI Spec 4.1 and must extend from the rear of the engine block to the

rear of the tail housing with a minimum of six (6) inch overlap where it is

fastened.

5.

All vehicles using an automatic

transmission must be equipped with a flex plate meeting SFI Spec 29.1.

Transmission-Manual:

1.

Non-OEM transmissions are prohibited.

The transmission must have been an option on a one ton or smaller truck.

Aftermarket internal components are permitted.

2.

A clutch meeting minimum SFI Spec1.1 or

2.1 is mandatory on all engines.

3.

All manual transmissions must be clutch

assisted.

4.

Sequential shifters are prohibited.

5.

All transmissions must have a flywheel

shield labeled as meeting minimum SFI Spec 6.3 or greater.

6.

Applications for which an SFI Spec

flywheel shield is not available may use a properly attached SFI 4.1 or 4.2 blanket that completely covers the bell housing. It must

attach to the rear of the engine block and extend rearward to the transmission

with a minimum of six (6) inch overlap where it is fastened. All transmissions

or clutch pedals will have a safety interlock switch so that vehicle will not

start in gear.

Turbocharger:

1.

S-4, GT42, HX50 and turbo of this type

is the largest turbo allowed.

2.

T-4 mounting flange is the largest

allowed

3.

No clipped wheels or step down covers.

4.

Billet compressor wheels are

allowed.

5.

A single .200 inch MWE groove maximum

allowed.

6.

Inducer bore must be non-removable.

7.

All air must go through the 2.5 inducer

bore and MWE groove,

8.

The wheel must protrude into the 2.5

bore 1/8 inch. Turbo checked with a 2.550 plug.

a.

6.4 Powerstrokes

will be permitted to run modified turbos as long as

the atmosphere turbo does not exceed the OEM straight bore dimension. (2.59)

9.

No TAPERED COVERS will be

permitted.

Water Injection:

1.

Water injection is prohibited. All

system components must be removed from the truck.

Wheelbase:

1.

The vehicle must retain the original

factory wheel base and track width.

2.

Cab and chassis trucks may not exceed

172 inch center to center of axles.

3.

Front dual-wheel spacers may be used

only with accompanying positive-offset dually style wheels.

ALL THE ABOVE

RULES WILL BE STRONGLY ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS.

THE OFFICIALS’ DECISIONS ARE FINAL! **The Head of Class/Tech

Official for each class will enforce all of the rules! Every vehicle will

be teched on a random basis at some point throughout

the season.**

5,500LB. Michindoh

Mods

Rules

locked 2016, 2017, 2018

Must also follow all general rules

listed above.

With

the exception of safety requirements approved by the board.

Weight:

1.

5,500lbs.

Driver:

1.

Must be 16 years of age or older

Tires:

1.

Whether U.S. or metric numbering system

– can be no larger than 18.4 x 38

2.

Any cut

3.

Aluminum and steel rims allowed

4.

Bias or radial

5.

No duals

Fuel:

1.

Commercial pump gas

2.

Race gas

3.

Aviation fuel

4.

No alcohol

5.

No nitrous oxide

6.

No pressurized fuel tank

Engine:

1.

American made automotive type engine no

larger than eight cylinders.

2.

Maximum 500 cubic inches, 1%

tolerance.

3.

Must be cast iron block, heads, with

visible OEM casting number – all must be same manufacturer. No after-market

allowed.

4.

2 valves per cylinder

5.

1 sparkplug per cylinder

6.

No overhead cams

7.

Must be naturally aspirated on

carburetion, dual carburetor tunnel ram allowed.

8.

Headers must exhaust in an upward

direction

9.

All tractors must be carbureted with no

fabricated sheet metal intakes.

10.

Distributors-any

factory or aftermarket distributor can be run as long as it is MSD 6AL

compatible.

11.

Ignition

– M.S.D. #6AL – 6420 or #6ALN – 6430 – rev limiter box with 7200 chip – Tech

officials will check RPM’s of the MSD box with an MSD test box and chips will

be tested with the same box for success and RPM’s, and shall not be any higher

than 7210. If chip is over 7210 it will be automatic disqualification resulting

in last place position of that event. MSD box must be mounted in a location

that is easily accessible and visible to the Tech official. Chip port must be facing an open position to

get test tool on easily. Chips will be removed and checked by a Michindoh

official after your pull. Then can be picked up after the class is over.

Tractor:

1.

2 wheel drive farm type tractors only –

with original transmission housing attached to the rear end – must have at

least one forward and one reverse operable gear – no planetaries

– no extra transmission or gearing of any kind outside of the tractor’s

transmission on the engine – Tractor gearing can be changed.

2.

Maximum length 14’’ from the center of

rear axle to the furthest point forward including weights.

3.

Must have a wide front end – Front tires

must track inside rear wheel tread

4.

Must have working brakes

Hitch:

1.

20” maximum height

2.

Hitch point 18’’ minimum behind

centerline of rear axle – the distance behind the hitch hole may not exceed

more than 1 ½’’

3.

Must be rigid in all directions

4.

Minimum opening 3 ¼ wide by 3 ¾ deep.

5.

Minimum of 1’’ thick maximum 1 ¼”

6.

Turn buckles or hitch adjustor cannot be

higher than the center of the rear axle

7.

No obstruction 5’’ wide and 24’’

directly about hitch hole

8.

Welds and hitch construction will be

inspected by Tech official for safety

Wheelie

Bars:

1.

Must support weight of tractor in its

heaviest class

2.

Must extend a minimum of 32’’ behind the

center of the rear axle

3.

Pads must be a minimum of 5’’ inches

square with trimmed corners optional and not more than 10’’ off the ground.

4.

Wheelie bars are to be mounted separate

from hitch

Miscellaneous:

1.

There will be a required driver safety

enclosure, any NTPA style roll cage, or

a minimum of 2’’ tubing or box tubing with at least 2 bars, with at least 2’’ of clearance between inner

fenders and tires. Tubing must be a

minimum of .090 thousandths of a inch wall thickness.

Roll cages may be inspected and stamped by tech officials with year of

inspection. Sonic test equipment for steel wall thickness may be used if

needed.

2.

Dead man throttle required – spring at

the carburetor return to idle

3.

Ignition kill switch required – must

stop fuel pump and ignition – must be mounted about the hitch plate – must run

electric fuel pump – easily accessible and visible to hitch man on sled.

4.

May only use an electric fan, no engine

driven fans allowed

5.

A

working

fire extinguisher – mounted within driver’s reach – must be readily accessible

and minimum of two pounds

6.

All belts must be 360 degree shrouded

with 1/16’’ steel or 1/8’’ or thicker aluminum.

a.

Harmonic balancer (SFI preferred) must

be surrounded 360 degrees by a min. 3/16” thick steel

– also a metal strap over the center of the balancer must be a min. of 3/16’’

thick and 3’’ wide, with a max. 1 1/8’’ hole for access to the crank center

bolt. Max one inch by one inch hole is allowed at the timing indicator marks to

allow for engine tuning. Entire enclosure must be mounted in at least 3 solid

points.

7.

Universal

joints, chain couplers, and/or driveshafts must be

surrounded 360 degrees by 1/4” or thicker steel (3/8" or thicker aluminum)

entire shaft length from the automatic transmission to the tractor transmission.

Round drive shaft cylinder required (one piece not cut or welded together is

recommended). Inside diameter of shield will be no more than 2" larger

than largest u-joint. If shaft cover is

cut hoizontal, vertical, or both, it must be bolted

on both ends of cut (minimum of 1” from edge of cut). Must also be bolted

entire length of cover with a maximum of 12” between bolt spacing. All

fasteners must be at least 3/8”- grade 8 bolts. Slip joint/ yoke shaft manditory. There will be NO HINGE STYLE fasteners permited. All yokes and u-joints must be entirely covered

360 degrees. Shield must be securely fastened to frame both ends and center. If

multiple piece shield all ends of shields must be tethered with a nylon strap

2”wide x 3/32” thick and fastened with 3/8” grade 8 bolts or larger. Tether

must have metal inserts for bolt to pass through. Must strap both ends of

shield and no more than 2’ apart the entire length of shield. Straps must be

bolted to both frame rails and loop around shield. Braided cable may be used

instead of nylon strap.

8.

Automatic transmission must be

surrounded by a SFI 4.1 or 4.2 rated transmission blanket at least 18’’ in

length. Blanket must be mounted to the block with no more than a 4’’ gap

between the block and the blanket and have at least 3 straps encompassing the

transmission. ¼ steel may be used instead with same dimensions applying. Must

be equipped with a SFI flex plate.

9.

Everyone must run an automatic

transmission with a torque converter – mounted directly to the back of the

engine.

10.

Side

shields – must be made from 1/8’’ or thicker steel or ¼’’ or thicker aluminum –

must cover from front to rear of block and cover from the bottom of the head to

2’’ below crankshaft center line – must be secured at all four corners

11.

Tractors

can be driven or are allowed to be towed around in the pit area.

Driver

Safety Equipment:

1.

Jackets and pants with a rating of SFI

3-2a1 and shoes with a rating of 3.3/5.

2.

Full face helmet – D.O.T. approved

3.

High back molded vinyl, fiberglass, or

aluminum race seat

4.

Four or five point seat harness

required.

5.

Automatic shifter activated reverse

clear lens back up light – with unobstructed view to hitch man on the sled

6.

All non – barbed fittings (cooling or

fuel) must be double clamped.

7.

Driver’s equipment must be on tractor

while being scaled. If equipment is not on vehicle tractor will not be allowed

to be scaled.

8.

Kill

switch must stop ignition and fuel pump

9.

Tractor must have a neutral start safety

switch

10.

Backup

light and kill switch must be easily accessible and seen by hitch man on sled

and may be checked randomly at pulls. At pulls colored tie straps will be

applied to kill switch to signify that tractor has been through tech.

ALL THE ABOVE RULES WILL BE STRONGLY ENFORCED

DUE TO YOUR SAFETY AND THE SAFETY OF OTHERS. THE OFFICIALS’ DECISIONS ARE

FINAL!

**The Head of Class/Tech Official for each

class will enforce all of the rules! Every vehicle will be teched on a random basis at some point throughout the

season.**

8,500# OPEN

$50 entry100% payback

Must also follow all general rules listed above.

Open class is subject to change at anytime by

board

Must meet all safety rules to class you

would normally run.

540ci maximum

HITCH

2WD Gas 30”

4WD

Gas 26”

Diesel

Trucks 24”

Farm

Tractors 20”

Driveshaft Loops:

2.

Drive

shaft loops required (3/4” or wide), 1/8” or thicker steel (1/4” or thicker

aluminum). No more than 2” larger than the largest u-joint. If cut in half,

must be bolted within 1” from ends and a maximum of 16” apart from loop to loop

(multiple loops). If using a one piece cover it must be bolted a maximum of 6”

apart the entire length and at least 1” from ends. All fasteners must be at

least 3/8”- grade 8 bolts. NO HINGE STYLE permited.

Must be securly fastened.

U-joint

shielding:

2.

All

u-joints and yokes must have a 360 degree cover, at least 6” long (covering

entire yoke and u-joint), 1/4” thick steel (3/8” thick aluminum). Inside

diameter of shield will be no more than 2" larger than u-joint. If cover

is cut in half it must be fastened no farther than 1” from ends with at least

3/8”- grade 8 bolts. Must be bolted a maximum of 6” from bolt to bolt. All intermidiate shafts need covered 360 degrees. NO HINGE

STYLE fasteners permited. Must be securly

fastened.

Harmonic Balancer:

1.

All engines must be equipped

with a harmonic balancer or dampener meeting SFI Spec18.1.

2.

All vehicals

are required to shield all rotating mass mounted on the front of the

crankshaft, if unobstructed. Shields to be from frame rail to frame rail and

top to bottom. Shields to be a minimum of .125” steel or aluminum fastened by

at least 2 evenly spaced 3/8” grade 5 bolts.

ALL

THE ABOVE RULES WILL BE STRONGLY ENFORCED DUE TO YOUR SAFETY AND THE SAFETY OF

OTHERS. THE OFFICIALS’ DECISIONS ARE FINAL!